Maximum Material Strength: The Critical Role of Equipment in Advanced Heat Treatments

In highly demanding industrial sectors such as steelmaking, aerospace, and energy, material strength is not optional, it is a necessary condition for safety, efficiency, and operational continuity. Subjecting a component to heat treatment does not simply mean heating and cooling it; it is a sophisticated process that defines the metal’s microstructure in service.

When materials must withstand temperatures above 1000 °C, corrosive atmospheres, and continuous mechanical stresses, the success of the heat treatment depends on a variable too often underestimated: the equipment used.

With over forty years of experience in the development and manufacture of ultra-resistant steel alloy components, Nicro positions itself as a strategic partner to overcome the typical challenges of this process and ensure the maximum material strength of the finished product.

The B2B Problem: Operational Fragility and Hidden Costs

The manufacturing and processing industries face three recurring challenges related to obsolete or standard equipment used in furnaces, or to the use of unsuitable materials—each with its own (including economic) consequences:

- Ineffective Uniformity: Equipment with poorly designed geometry or materials deformed by heat fails to provide uniform heat transfer to the load. The result is final products with inconsistent material strength, leading to waste or premature failure.

- Unexpected Downtime: Equipment made from generic alloys is prone to rapid oxidation, creep deformation (plastic deformation under load at high temperature), and structural failure. This results in frequent replacements, costly downtime, and productivity losses.

- Standardized Design: Every furnace, process, and load type requires specific mechanical and thermal support. The use of standard, non-optimized equipment for a given plant drastically reduces both its effectiveness and service life.

The Nicro Solution: Custom Equipment and Advanced Alloys

Nicro was founded precisely to address these challenges, specializing in the design and manufacture of equipment used in all types of heat treatment furnaces (static, single-chamber, continuous, and pit furnaces, in both atmospheric and vacuum conditions). Our solution is built on three interconnected pillars: specialized design, material selection, and certified quality.

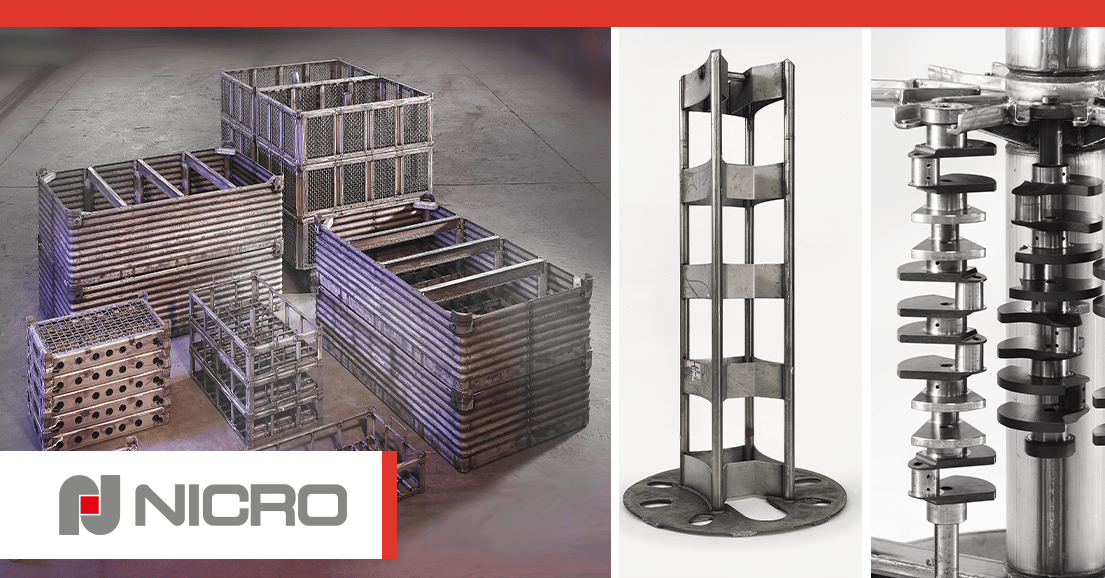

Our design department goes beyond drafting—it actively collaborates with customers (engineers and production managers) to develop and prototype solutions that maximize load density and thermal uniformity. Through in-depth analysis, we deliver customized solutions such as baskets, grids, and fixtures that optimize heat distribution while reducing cycle times and energy consumption.

We can redesign and reproduce components on request, even in specific materials, overcoming the limitations of existing or discontinued equipment, while enhancing their performance and service life.

Withstanding the Extreme: Our High-Nickel Steel Alloys

The true material strength of equipment depends on the quality of the alloy. Nicro uses carefully selected materials chosen for their ability to perform under extreme conditions—where standard stainless steels would quickly fail.

We use alloys such as:

- AISI 321 (1.4541), AISI 309 (1.4828), AISI 310 (1.4845), AISI 314 (1.4841): Austenitic stainless steels resistant to oxidation and corrosion at high temperatures.

- Avesta 253MA (1.4835): A high-temperature alloy with excellent mechanical strength and outstanding oxidation resistance up to 1100 °C.

- Alloy 800H: Good creep-rupture properties; good resistance to reducing, oxidizing, and nitriding atmospheres; metallurgical stability in long-term applications at high temperatures up to 1050 °C.

- Alloy 600: An alloy offering good resistance to oxidation, stress-corrosion cracking, and dry chlorine and hydrogen environments up to 1100 °C.

- Alloy 601: Excellent oxidation resistance, good resistance to carburizing conditions, strong mechanical properties, and good resistance to stress corrosion up to 1100 °C.

- Nicrofer 6025HT (2.4633): A high nickel–chromium alloy specifically developed for critical applications requiring maximum resistance to creep and oxidation under continuous service.

The use of these alloys reduces maintenance needs, extends equipment life, and ensures that the geometry of the support structure remains stable—guaranteeing repeatability and consistent quality in the heat treatment process.

Your Guarantee of Safety and Durability

Reliability is not a claim, it’s a certification. Choosing Nicro as your supplier provides undeniable proof of quality and manufacturing rigor:

- ISO 3834-2:2021: This certification, specific to the quality of fusion welding processes for metallic materials, is essential. It ensures that every welded joint in our critical equipment is strong, reliable, and capable of withstanding thermal stresses without failure.

- ISO 9001:2015: Guarantees a strict quality management system at every stage—from raw material reception to final testing.

- ISO 14001:2015, ISO 45001:2018, and ISO 50001:2018: These certifications highlight our commitment to sustainability, operational safety, and energy efficiency, offering a partner that is not only technically skilled but also ethical and responsible.

The material strength of your finished product is directly proportional to the quality and efficiency of the support equipment used during heat treatment. Choosing Nicro means relying on a company that combines the expertise of an outstanding design department, the use of ultra high-performance steel alloys, and a production process certified by the most rigorous international standards.

Contact the Nicro design department today for a personalized technical consultation. Discover how our custom heat treatment solutions can enhance efficiency, reduce maintenance costs, and ensure maximum strength for the critical materials in your plant.