Services

Competence and precision

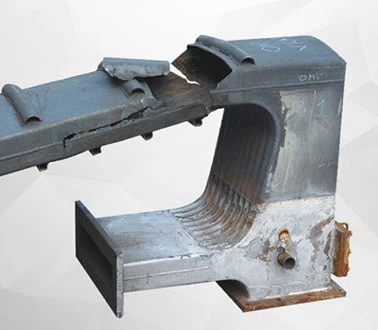

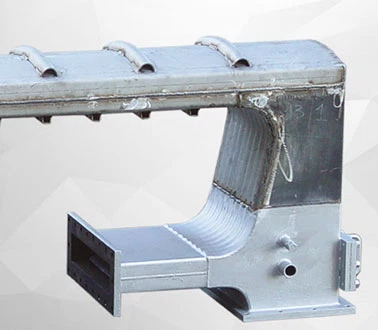

Repairs

NICRO is capable of reconditioning and repairing several kinds of products, thanks to a dedicated and suitably equipped workshop.

Materials

research

Every application or industrial process needs suitable temperatures and, subsequently, materials capable of withstanding such temperature, wear, or corrosive working conditions. NICRO makes available its vast experience and knowledge of raw materials to find the best solution.

Product

engineering

This important experience, accrued in over than 40 years, puts us in condition to face any situation and find the most appropriate solutions through the fine-tuning of construction drawings, besides, obviously, the selection of the most performing materials.

The same reverse engineering process is made possible by a tight-knit and competent team, used to face challenges of any kind, with an attitude tuned towards problem solving.

Product Quality

Control

Each product manufactured by Nicro undergoes meticulous quality control, which includes dimensional checks, material certification, and non-destructive testing where applicable. We use certified measuring instruments that are regularly calibrated and standardized procedures to ensure compliance with the required specifications. Our quality system complies with ISO 9001:2015 standards and guarantees full traceability of every production batch.

VT – Visual Testing of Welds Visual testing (VT) is the first step in evaluating the quality of a weld. At Nicro, it is performed by specialized technicians who visually inspect welded joints for imperfections, misalignments, or surface anomalies. This inspection is essential to ensure that welds meet the acceptance criteria established by technical standards.

PT – Liquid Penetrant Testing Liquid penetrant testing (PT) is used to detect surface discontinuities invisible to the naked eye, such as cracks or porosity. It is a non-destructive method primarily applied to welds and critical surfaces to ensure the integrity of the product. The test is performed by qualified personnel according to international standards.

RT – Radiographic Testing Unlike the first two methods, radiographic testing (RT) allows for volumetric examination of welded joints to identify any defects not visible on the surface. This technique is essential in high-criticality sectors, where safety and material strength are key requirements. Nicro collaborates with certified external operators for performing radiographic inspections and relies on internal staff for reading and interpreting the results.

Packaging

and shipping

Once the production is complete, the finished product undergoes the tests requested by the customer’s order, and then it can be finally packed for shipment.

Our experience, with many different foreign markets, makes us especially careful in identifying the best solution for the shipment of our products, using both fumigated wooden special boxes, or special structures in metal tubes to provide a safe and easy transport.